The Perception of Door Handles

The doors throughout the house are original and we want to strip them down and paint or varnish them. In some rooms they also need adjusting to fit properly. We’ve already had the one for my study done but, because stripping the paint is very labour intensive, we want to do it ourselves. We just need to remove the door handles and locks first. Which is where the problems start.

Because the handles are loose in the living room, we know how they work: each has a shaft that fits in a hole of the other. A screw next to the lock holds them in place. And I’ve already managed to remove the ones in the kitchen.

But we’re starting with the cellar door. And they won’t budge. I’ve tried everything, even with two people. We have to assume that there has been some kind of corrosion between the different metals.

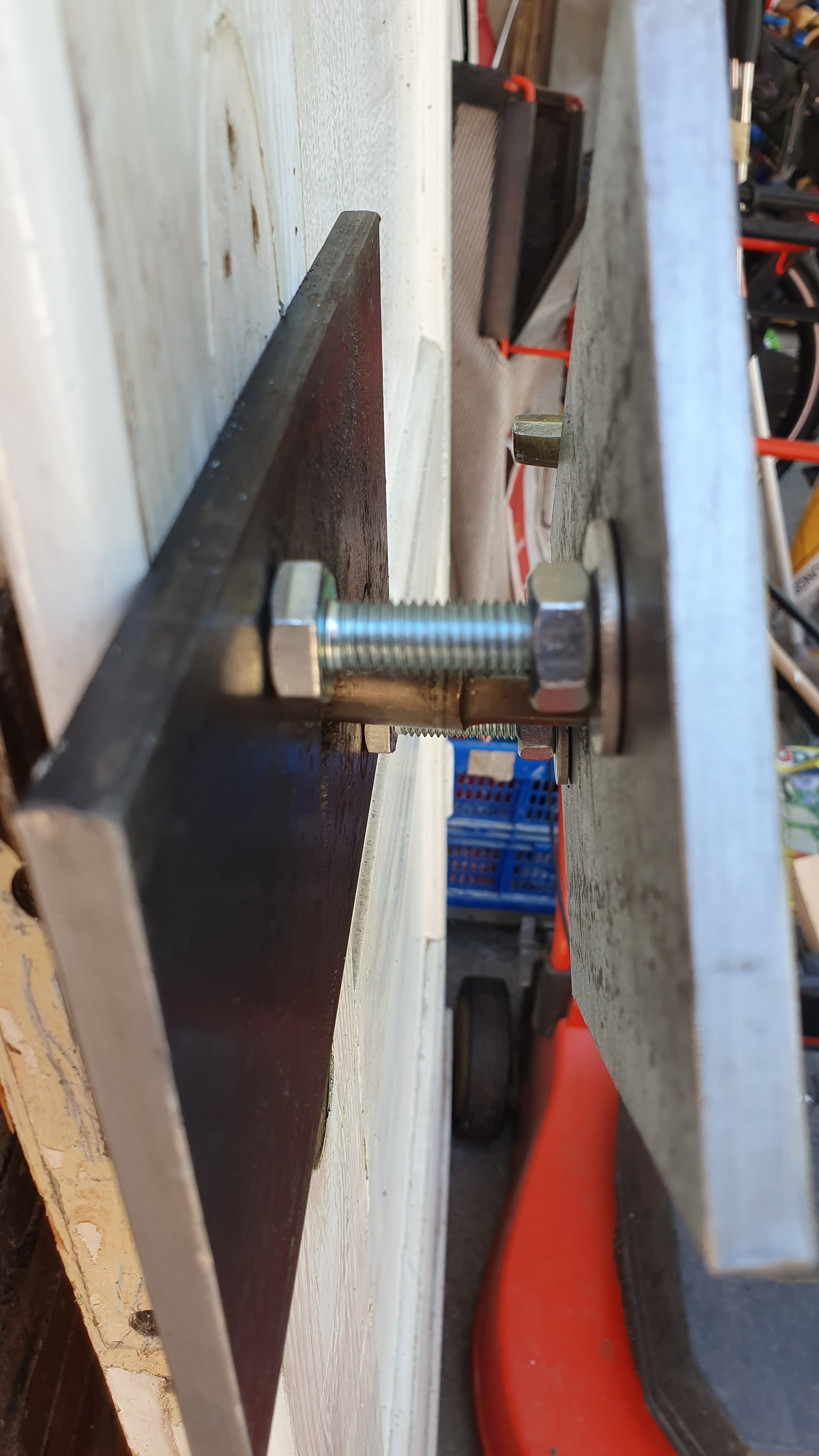

Ideally, I’d use some kind of screw jack to ease them apart. Except I can’t find anything suitable. So I decided to have a go at making something myself. The idea being to use two bits of steel and a couple of bolts for a kind of reverse vice. Got the steel from the DIY shop on Saturday, just need to drill some holes.

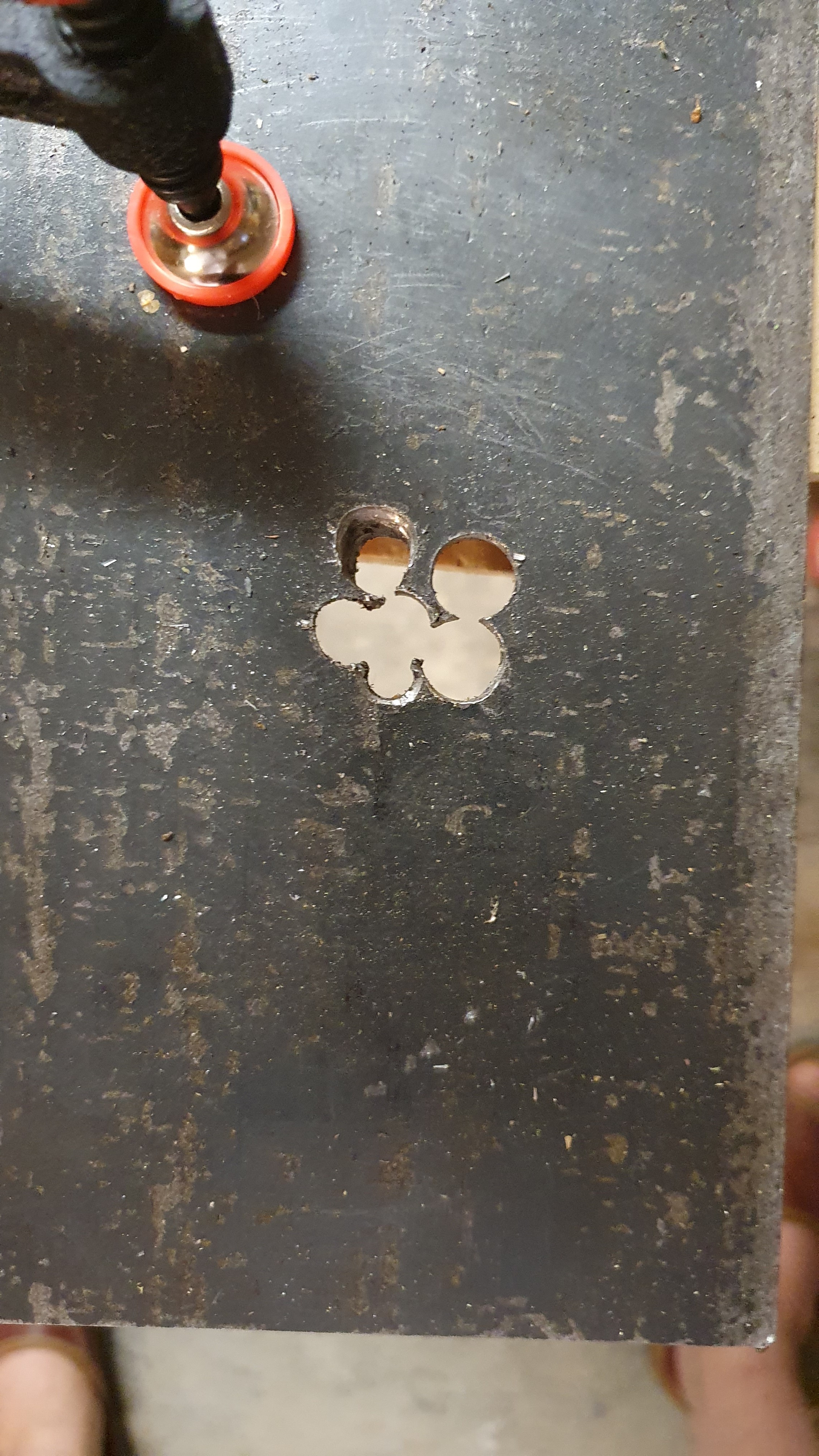

Well the drilling didn’t go too bad; only broke a couple of bits The steel plates are probably thicker than necessary but that was what they had in the size and I want large plates to spread the force.

Turning that collection of holes into a single one large enough to fit over the door handle was going to take either a lot of filing or grinder. The watchmaker files my dad gave me years ago are too small and mostly bald anyway. So new files and some grinding bits were required. Plus at least one g-clamp for a makeshift workbench.

The round file made short work the bits between the holes and the grinders were able to extend the towards the 3cm needed. Fortunately, precision isn’t required here, the plates just need to be able to go over and along the handles, rotating 180° in the process.

The second plate needed more a bit more work

But it too was ready quite quickly. I was really impressed that my cordless drill was able to manage this. Already impressed with it for drilling in walls but steel is a whole lot harder, literally.

Of course, it turned out the bolts I bought weren’t quite right, so off again to the DIY shop.

Then plenty of trial and error to find the best position: the idea being keep as close to the centre of the axis of the handle as possible. Easier said than done with handles that curve, but eventually I found something that worked.

And yet it moves!

The only bolts I could this morning find were too short to finish the job, even with some extra washers. And, even having moved the door handle more than a cm, you still can’t pull them apart: the rust on one side is plain to see. The rest is just a matter of time.

Certainly not the only way to do this and the execution was far from perfect, but if it works, it works. But I also hope this will be the only door that need this kind of treatment!